Details, Fiction and precision machining

Elcon provides CNC machining and turning services held to that exact same good quality regular Together with the experience to fulfill your machining needs.

Precision machined products are all around in daily things which include car or truck engines, electric powered motors or even clocks. Nations for example Switzerland and Germany Have a very track record for there higher expectations of precision engineering and now still do a very good job of it. Other nations also have a lesser of this status such as Japan and Good Britian.

The method of forces that act for the duration of machining may very well be reduced to just one resultant pressure. Even though the Answer of functional difficulties would not require familiarity with the magnitude of this power, the elements from the power are very important. They may be the cutting drive Pz performing within the plane of reducing while in the direction of the principal motion; the radial ingredient Py, acting perpendicular into the axis of the workpiece (in the situation of turning) or on the axis with the tool (throughout drilling and milling); as well as feed pressure Px, performing during the route of feed.

The Basic Principles Of machining

The confront milling process can in principle create very flat surfaces. On the other hand, in apply the result usually displays noticeable trochoidal marks next the movement of points about the cutter's conclusion encounter. These revolution marks give the characteristic end of the confront milled area. Revolution marks may have significant roughness dependant upon components including flatness of your cutter's finish face along with the degree of perpendicularity among the cutter's rotation axis and feed way.

Is exact the adjective kind of precision? The term precision is equally a noun and an adjective; illustrations: Adjective: Acme tends to make precision instruments . Noun: Acme tends to make instruments with precision . The noun type for that adjective exact is preciseness.

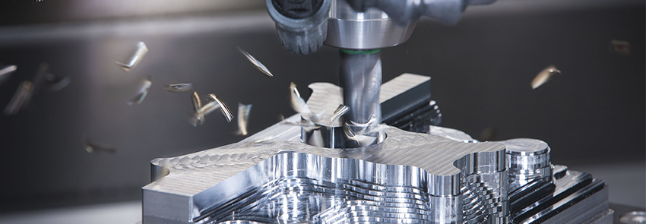

The milling procedure gets rid of materials by undertaking numerous independent, tiny cuts. This can be completed by making use of a cutter with lots of tooth, spinning the cutter at superior speed, or advancing the material with the cutter slowly; most frequently it really is some mix of these a few methods.

These devices are operated by specialized and trained machinists. The precision machining system will involve a cutting tool that eliminates material with the workpiece. To ensure that the chopping Resource to accomplish its job, it need to be moved in Instructions specified to generate the right cut. This Major motion is known as the “slicing pace.†The workpiece may also be moved, generally known as the secondary movement of “feed.†Collectively, these motions as well as the sharpness on the cutting Device allow the precision machine to function. Learn More:

Get a scope zooming manage one week in the past and hunted with it final evening. Gentleman it can make it a lot eas...ier to vary you aim now. Very suggested See Far more

The Basic Principles Of machining

The slicing surfaces of the milling cutter are typically made of a tough and temperature-resistant material, so they have on gradually.

CNC machines can exist in pretty much any in the types of guide equipment, like horizontal mills. By far full article the most Innovative CNC milling-equipment, the multiaxis device, add two much more axes As well as the 3 standard axes (XYZ). Horizontal milling machines also have a C or Q axis, making it possible for the horizontally mounted workpiece being rotated, primarily allowing asymmetric and eccentric turning.

Machining operations generally divide into two categories, distinguished by objective and cutting ailments:

Relevance ranks synonyms and indicates the most beneficial matches based on how intently a synonym’s sense matches the feeling you selected.

5 Simple Techniques For machining

Besides dimensions and precision, the principal distinction between these hobby-sort devices and larger real vertical mills would be that the X-Y desk is at a fixed elevation; the Z-axis is managed in mainly the same style as drill push, where by a larger vertical or knee mill has a vertically fastened milling head, and modifications the X-Y table elevation. In addition, a mill-drill generally employs a normal drill push-sort Jacob's chuck, rather then an internally tapered arbor that accepts collets. They are commonly of reduce quality than other kinds of machines, but still fill the pastime position nicely given that they are generally benchtop equipment with smaller footprints and modest selling price tags. Horizontal milling device[edit]